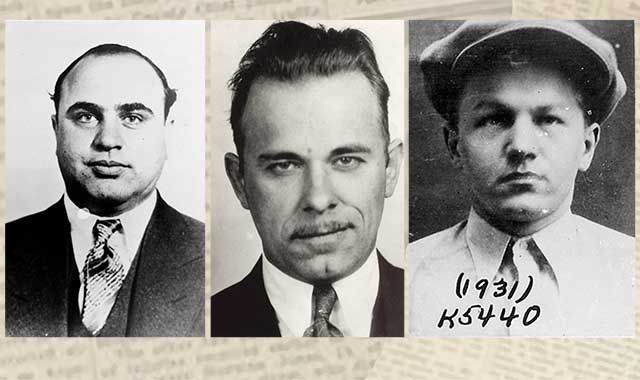

Growing up, Mike Kainz heard the family tales of his great-grandfathers and their downtown Chicago dairy, at Mohawk near Lincoln Park. During Prohibition, they converted half of the dairy into a brewery, rolling kegs out the back door for Al Capone’s men to pick up.

“The business was long gone by the time I came along, but those stories were part of my childhood and family history,” says Kainz, co-owner and brewmaster of The Onion Pub & Brewery, 22221 Pepper Road, Lake Barrington. It was this legacy that eventually led the economics and French major to become a brewer. Kainz attended Dennison University, a small, private liberal arts school in Ohio. During his junior year, while studying in Paris, he was exposed to many styles and flavors of beer, having previously sampled only the larger U.S. brands.

“In the 1880s, there were roughly 4,500 craft brewers in America,” Kainz says. “Today, there are about 1,400. Prohibition killed the brewing craft. The only ones that could survive were the big companies, those that were able to convert to some other business during that time. But after 14 years – the length of Prohibition – the beer that was being produced was a watered-down, pale version of the real thing. It took until the 1970s for brewing to recover some of its pre-Prohibition status. So, when I was in Europe, I was blown away by the kinds of beer I tasted. I hadn’t realized the art and chemistry involved in the process.”

What “sealed the deal,” he says, came after graduation, while serving in the Peace Corps in North Africa.

“Brewing goes back to the ancient Sumerians,” Kainz explains. “Every society, in every part of the world, creates a fermented beverage of some kind, from whatever grain is on hand. My wife was in the Peace Corps at the same time I was, in West Africa, and we both saw how culture and economy were tied to the craft. Women are the brewers in Africa – they were in ancient times, too – and on weekly market days, someone always had a fresh batch of local elixir, made from millet, for sale. People would dip into the open keg and drink it right there – out of a rather small gourd, because it’s pretty potent stuff. So they would get a nice, warm feeling, and then go about their business, shopping and selling and bartering and connecting with others. It was part of the social ritual that was market day. And so, it was seeing its important social and cultural aspects, coupled with my earlier Paris experience, that made me realize – over in Africa, at about the age of 22 – that I needed to get back to my family’s roots and become a brewmaster.”

Returning to the States, Kainz spent several years in California, learning to make wine. “The chemical process is very similar,” he says. “I worked every job, from planting and harvesting, to fermenting, bottling and marketing. Then, I came back to Chicago and attended Siebel World Brewing Academy, one of only a handful of Master Brew programs in the country, and became a certified Master Brewer. Then, my wife and I convinced my parents to let us set up in their garage, using a couple of stainless steel dairy containers I salvaged out of a cornfield, wading through waist-deep snow to get them.”

That was in 1995. The Wild Onion Brewing Co. began selling its flagship brew, Paddy Pale Ale, in 1997, and shortly after, moved operations to a warehouse just down the street from its present location, still brewing in the repurposed dairy tanks. Kainz co-owns the business with wife Jennifer, parents Sue and Joe, and brothers John and Pat. They broke ground on the new building in 2002, next to an 11-acre lake that was once a gravel pit, and opened in 2003. The establishment’s moniker comes from the origin of Chicago’s name, shikaakwa, a Native American term referring to the wild onions that grew in abundance at the watershed of the Chicago River when French traders first arrived.

Dairy tanks now gone, the basement on Pepper Road is brew central, with plenty of room to expand operations.

“Basically, there are two types of beers – lager and ale,” says Kainz. “Lager ages longer and ferments from the bottom up. It’s crisper, cleaner, and comparable in wine to a white. Ale doesn’t age as long and ferments from the top down. It’s floral and fruity, more complex than a lager, or similar in wine to a red.”

First in the brewing process is creating mash from the malted barley, which can be roasted, or even unmalted, to change the qualities it imparts. This ingredient contributes most to the beer’s overall color, flavor, body and aroma.

In the barley room, one 40-lb. bag at a time, the grain is dumped manually into a barrel and then sucked into a hopper, where it’s run through a two-roll mill. “This milling cracks the husk – we don’t want to crush or grind it – and releases the enzymes present in the barley that convert the starches to sugar, which is what ferments,” Kainz explains. “This is a base malt, but there are specialty malts that don’t really help to convert the starches, but add characteristics like extra foam or certain flavor profiles.”

Dry-roasted malts are used most often in darker ales, for instance, and can add tones of chocolate or coffee.

Next, in mashing, the cracked barley is placed in hot water, where it is heated to 154 degrees F. The mash is then held there for about an hour to allow the various enzymes to work their magic. This takes place in the brewhouse, where reverse osmosis filtered water is used to make the beer.

When the process is complete, the mash is heated to around 170 degrees Fahreheit, to deactivate the enzymes, and the highly-sugared water is strained from the grains. “The mashing takes a couple of hours, usually,” Kainz says. “We use 5 gallons of water to produce 1 gallon of beer, but we filter the leftover and pump it out into the lake, rather than dump it into the sewer system.”

The resulting liquid, known as wort, is transferred to the brew kettle, where hops, yeast and other ingredients are boiled with it. “The yeast, of course, reacts with the sugar to cause fermentation,” says Kainz. “Hops add bitterness, flavor and aroma. In the days before refrigeration, they were used as a preservative, as well as a flavoring agent, because they contain an antibacterial agent.”

The wort must be cooled prior to fermentation, and this is done at Onion Pub & Brewery in a special system brought over from Europe. One refrigeration unit holds liquid-filled plastic orbs about the size of a baseball. The liquid inside the balls is frozen, similar to plastic ice cubes consumers can buy. The unit circulates air and draws cold from the orbs as needed.

The brewery produces about 20 different beer varieties annually. There are six on tap year-round, and then seasonal brews and what Kainz calls “just for funs” are offered for limited times during the year. The kegs of brew are stored in a chilled room and directly tapped to the bar above them.

“When you drink it here, the beer travels less than 40 feet from the keg to your glass,” Kainz declares with a grin. “You can’t get much fresher than that!”

The pub and brewery have about 60 full- and part-time employees. The servers are trained in helping their customers to choose beers that fit their tastes and pair best with food orders. The menu offers eclectic pub fare, from the compulsory wings and burgers to veggie panini and bratwurst sliders, along with entrées like baby back ribs, steak and pasta.

“The seasonal aspect is especially fun, from the brews to the food,” says Kainz. “The chef uses as much locally-produced food as possible, and gears the menu to match the seasonal cravings we have. Seasonal changes are reflected in the beer, too. People love our specialty brews, but when they’re gone, they have to wait a year to get them again. We went through our Oktoberfest and Pumpkin Ale very quickly. Solstice Jo and Winter Warmer are our winter seasonals, and I think our neatest. We brew them on the longest day of the year, so that they’re ready when we celebrate the shortest day of the year. How’s that for cyclical?”

Kainz says the business is focusing on the brewery and outside beer sales. Onion Pub does its own canning and sells the brews through local businesses. The brewery has three employees. Mike Payson, a liberal arts graduate of Northern Illinois University, has recently been taken on as an apprentice brewer. He’s worked as bartender and server and, he says, “I want to know everything about brewing.” Pete Janusas is the assistant brewmaster. “We couldn’t do what we do these days in the brewery without Pete,” says Kainz. Also, the pub just promoted another longtime employee to full-time sales rep.

“We really want to expand the brewery and our canning operation,” Kainz says. “We plan to triple or quadruple production in the next two years.”

While Kainz calls the pub “locationally challenged,” it’s in the exact place the family planned on from the beginning.

“We started out with the goal of opening a pub, and we had always loved this particular spot,” Kainz says. “Being out here is a hindrance, but it’s also a help. People like it that we’re off the beaten path and that they have to work a little to find us. The lake is beautiful, and beyond it are wetlands. The ground is very porous and drains naturally into the Fox River. We wanted to use alternative energy, and the lake made geothermal a no-brainer.”

Geothermal energy is used to heat and cool The Onion Pub. The lake has 200 feet of tube looping away from and back to the building, through which flows a liquid similar to the refrigerant used in air conditioners and refrigerators. Whereas traditional refrigeration systems send this medium in one direction only, and expel the unused energy (think of the hot blast coming from under your fridge when it runs), geothermal systems can send it in both directions, through the closed loop, to create either hot or cold, and then release the extra energy (the hot or cold air) back into the lake or the earth. The unit uses no fossil fuels and creates no waste.

Many other aspects of The Onion Pub are ecofriendly. The exterior frame is constructed of Solarcrete, an energy-efficient building system that uses EPS foam and concrete to build walls that provide insulation close to R-40 (fiberglass insulation used in standard 2 x 6 wood framing achieves about R-17).

Inside, the beams supporting the cathedral ceiling are crafted from huge Douglas firs that were not harvested live. “All of these beams were made from timber that was already on the forest floor, and some are more than 250 years old,” Kainz says, with a tone of reverence. “It’s amazing to think that trees we used in here were alive before we were actually a country.”

A stone fireplace, open on both sides, divides the bar area from the dining room. The owners added a banquet room last year that doubled the facility’s square footage; overlooking the lake, with a solid wall of windows, it accommodates 250, and a divider allows for two events at the same time.

The Kainz family has a great deal of sweat equity invested, too. They removed a layer of artificial turf that surrounded the 11-acre lake, placed there by a SCUBA instructor who used the flooded gravel pit for lessons and diving. “There’s a Sikorski helicopter and half the fuselage of a 707 sunk in there for the divers,” Kainz says. “We replanted the banks with native plants, and we’re working with Citizens for Conservation to eliminate invasive species.”

They put in a waterfall and added a large patio with a hop vine garden. “Hops are amazing plants,” Kainz explains. “They grow 18 to 30 feet in one season. The vines are thick and woody, the dark green leaves fuzzy and heart-shaped, with scalloped edges, and the cone-shaped blooms are a beautiful color that’s hard to describe, almost a translucent green. They provide a gorgeous canopy in the summer.”

Despite its success, The Onion Pub & Brewery is a work in progress. The family is still landscaping around the lake, trying to camouflage some of the light industrial businesses that have sprung up since they opened their doors. In December, Kainz himself was building an extra room downstairs, to house aluminum cans for the expanding canning business. The basement is much larger than needed for current brew operations, but that was by design: “Even though we planned on the pub, the brewery is the heart and soul of the operation,” says Kainz. “We knew that coming in, and we wanted to make certain we had room to grow.” ❚